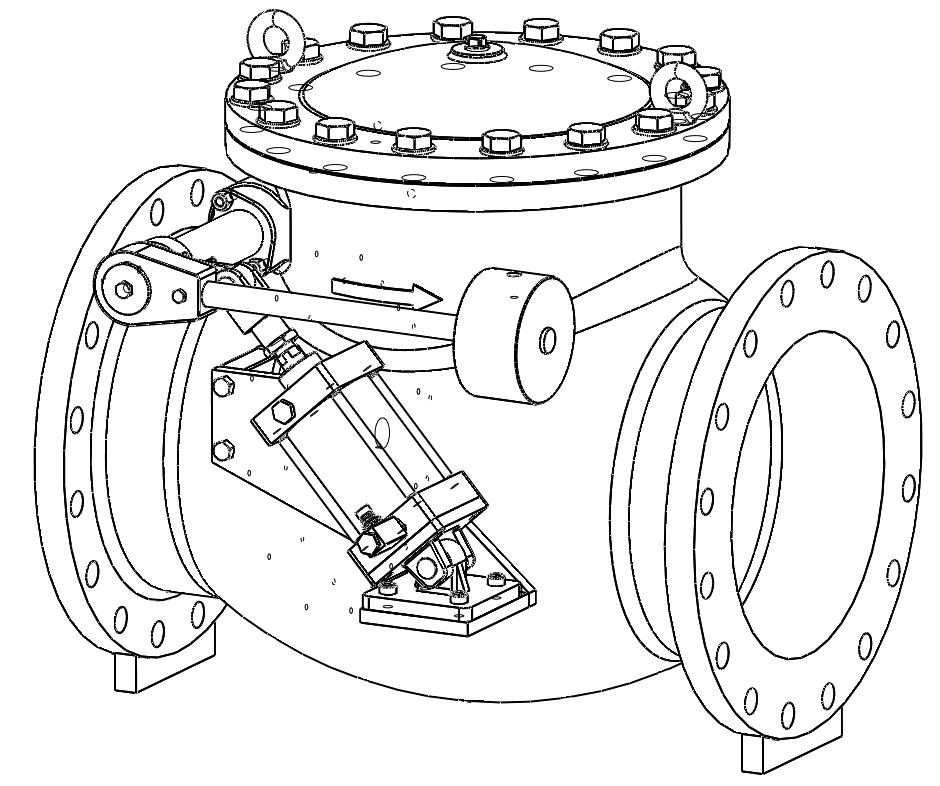

Air cushioned cylinder Swing Check Valve

What's air cushioned cylinder cast iron swing check valve?

Air cushioned cylinder Cast Iron Swing Check Valve is a type of swing check valve mounted with air cushion cylinder to prevent slam and water hammer.it consists of a valve body,a bonnet,and a disc that is connected to a hinge. The disc swings away from the valve-seat to allow flow in the forward direction,and returns to valve-seat when upstream flow is stopped,to prevent back flow.it allows full,unobstructed flow and automatically closes as pressure decreases.These valves are fully closed when the flow reaches zero and prevent back flow.Turbulence and pressure drop within the valve are very low.The valve is opened by the fluid flow in one direction and closes automatically to prevent flow in the reverse direction.

the valve is made of cast iron,ductile iron, is mainly used for water supply and drainage system, and other industrial sectors of the pipeline outlet to prevent medium countercurrent in low pressure and normal temperature.it could be mounted with closure control devices include Air Cushioned Cylinder, Oil Controlled Cylinder, Bottom Mounted Buffer, Lever & Spring and Lever & Weight.

Main features of air cushioned cylinder cast iron swing check valve

Features and benefits of Cast Iron Swing Check Valve

- *Trouble-free operation and easy maitanance

- *Full bore flow area, lower flow resistance.

- *Prevent medium back flow and eliminate destructive water hammer when the valve close. Protect the pipe system.

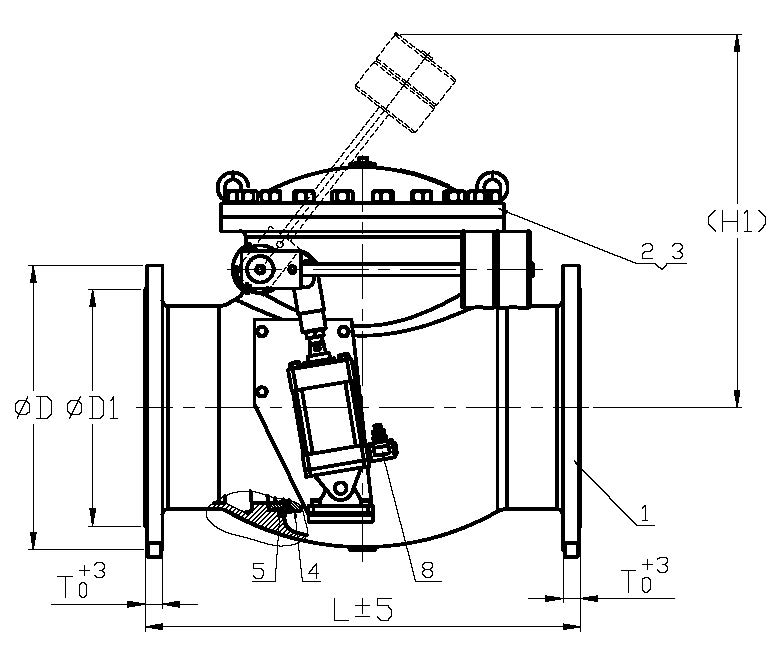

- *Fitted with cushion cylinder and lever weight, connected with disc by same shaft. The open and close time or speed can be adjusted by regulating valve and slide weight.

- *Sealing performance stable, reliable and wear resistance. Long use life, No vibration, No noise.

Working principal of Air cushioned cylinder Cast Iron Swing Check Valve:

- 1. When upstream pipe increase the water pressure, the valve disc will be pressed open.The disc shaft will drive the cylinder piston and the lever and weight up.

- 2. When the upstream water pressure higher than the valve open pressure, the valve disc will be pressed open. The cylinder piston will be drive open and inhale. When the upstream water pressure stop or back pressure, the valve disc will be close quickly by the disc deadweight, lever weight and back pressure. The cylinder piston fall down and the air inside the cylinder will start to produce damping force. More closing to the valve seat, more damping force it happened. When the disc closing to 30% open position, the damping force will be significantly increased. The disc will start to close slowly.

- 3. The closing speed of the disc can be adjusted by the regulating valve on the cylinder. Turn the knob of the regulating valve clockwise will increase the damping force of the cylinder and slow down the close speed of the disc; turn the knob of the regulating valve of the cylinder anti-clockwise will speed up the close of the disc. The lock nut clockwise adjustment after the completion of the can lock position at this time.

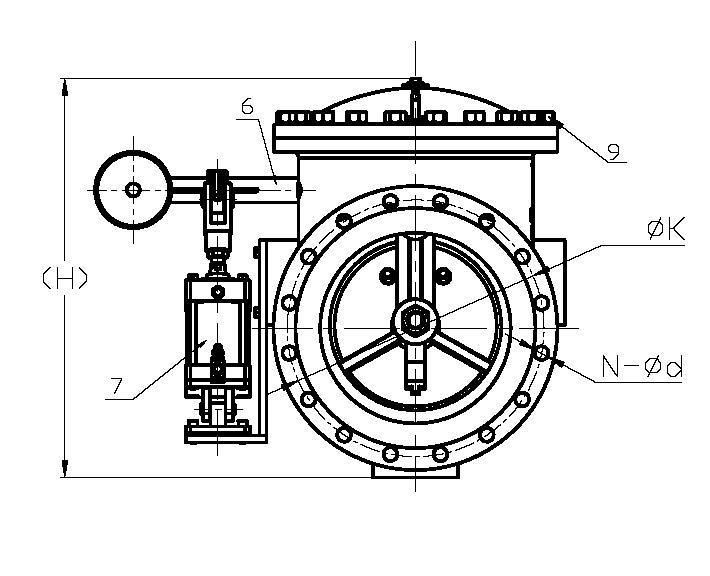

Technical specifications of cast iron swing check valve

Technical specifications of Air cushioned cylinder Cast Iron Swing Check Valve

| Design and Manufacture | BS5153/DIN3202 F6/AWWA C508 |

| Face to face | EN558-1/ANSI B 16.10 |

| Pressure rating | PN10-16,Class125-150 |

| Nominal diameter | DN50-DN600,2″-24″ |

| Flange ends | EN1092-1 PN6/10/16,ASME B16.1 Cl125/ASME B16.5 Cl150 |

| Test and Inspection | API598/EN12266/ISO5208 |

| Body and disc | Cast iron,Ductile iron |

| Air cushion cylinder | Aluminum alloy |

Product Show:

Application of air cushioned cylinder cast iron swing check valve:

This kind of Cast Iron Swing Check Valve is widely utilized in pipeline with liquid & other fluids.

- *HVAC/ATC

- *Water supply and treatment

- *Food and Beverage Industry

- *Sewage system

- *Pulp and Paper Industry

- *Industrial environmental protection