Ball Check Valve

What's Ball Check valve?

Check valve is type of valve for uni-directional purpose,also as non-return valves.

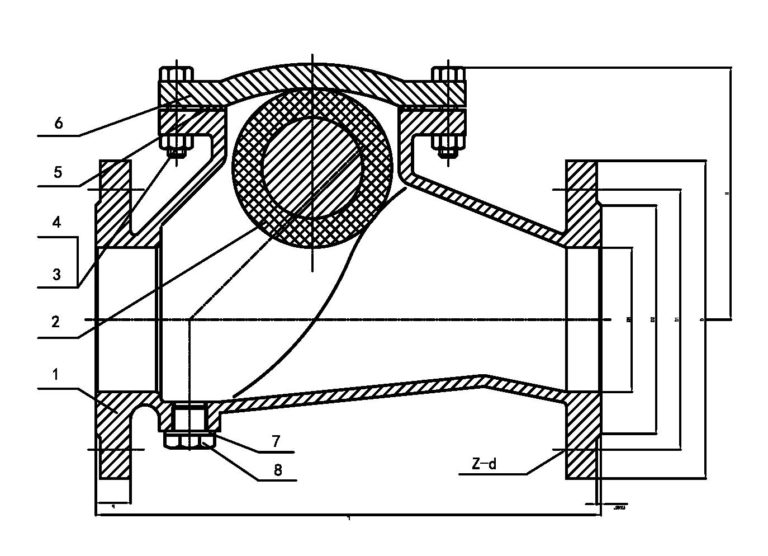

A Ball Check Valve is a simple and reliable valve with a spherical ball as the only moving part to block the reverse flow. Due to its simple flow efficient and virtually maintenance-free design the valve is commonly specified and used in submersible wastewater lift stations.The full-ported valve seat is uniquely designed allowing the ball to seat leak-tight without getting wedge into the valve seat. For vacuum or anti-flooding valve application, a "floating" rather than "sinking" ball is used.

Ball check valves contain a ball that sits on the seat, which has only one through-hole. It functions by means of a ball that moves up and down inside the valve. The seat is machined to fit the ball, and the chamber is conically shaped to guide the ball into the seat to seal and stop a reverse flow.The ball has a slightly larger diameter than that of the through-hole (seat). When the pressure behind the seat exceeds that above the ball, liquid is allowed to flow through the valve. But once the pressure above the ball exceeds the pressure below the seat, the ball returns to rest in the seat, forming a seal that prevents backflow. The ball moves up and down inside the valve depending on the flow and seals against the machined seat when no flow or reverse flow occurs and seals against the seat to stop the reverse flow. the check valves that have Buna-N lined ball as standard and with corrosion-resistant phenolic balls for abrasive media. Ball check valves are typically preferred for use in pumping stations as they are self-cleaning as the ball rotates during the operation and are vertically maintenance-free. If a ball check makes noise it is typically due to insufficient pump capacity or water hammer issues.

Main features of Ball Check valve

Features and benifits of Ball Check Valve

- *ball check valve is a simple and reliable valve with a spherical ball as the only moving part to block the reverse flow,maintenance-free design,suitbale for submersible wastewater lift stations.

- *The full-ported valve seat is uniquely designed allowing the ball to seat leak-tight without getting wedge into the valve.

- *Nortech Ball Check Valve are self-cleaning, as the ball rotates during operation which eliminates the risk of impurities getting stuck on the ball.

- *A full and smooth bore ensures full flow with low pressure loss and eliminates the risk of deposits at the bottom that could prevent tight closure.The standard ball is designed with a NBR rubber lined metal core, and the rubber hardness is optimized to prevent the ball from getting stuck in the seat. Balls of polyurethane are suitable for abrasive media and when different balls weights are needed to prevent noise and water hammer.

Technical specifications of Ball Check valve

Technical specifications of Ball Check Valve

| Design and Manufacture | BS EN12334 |

| Face to face | DIN3202 F6/EN558-1 |

| Flange end | EN1092-2 PN10,PN16 |

| Body | Ductile iron GGG50 |

| Ball | Ductile iron+NBR/Ductile iron+EPDM |

| Nominal diameter | DN40-DN500 |

| Pressure rating | PN10,PN16 |

| Suitable medium | Water,sewage,etc |

| Service temperature | 0~80°C(NBR ball),-10~120°C(EPDM ball) |

Product Show:

Applications of Ball check valves

This kind of Ball Check Valve is widely used in wastewater applications, power plants and process industry. The ball check valve is suitable for use in polluted media (up to 120˚F) as the ball shaped valve prevents the buildup of dirt. Typically a wastewater lift station will have a ball check valve to prevent reverse flow. it'a also widely utilized in pumping stations that are rarely attended, since they demand only limited maintenance, typically if the ball makes noise caused by insufficient pump capacity or water hammer.