Bellow Seal Globe Valve

What is Bellows Seal Globe Valve?

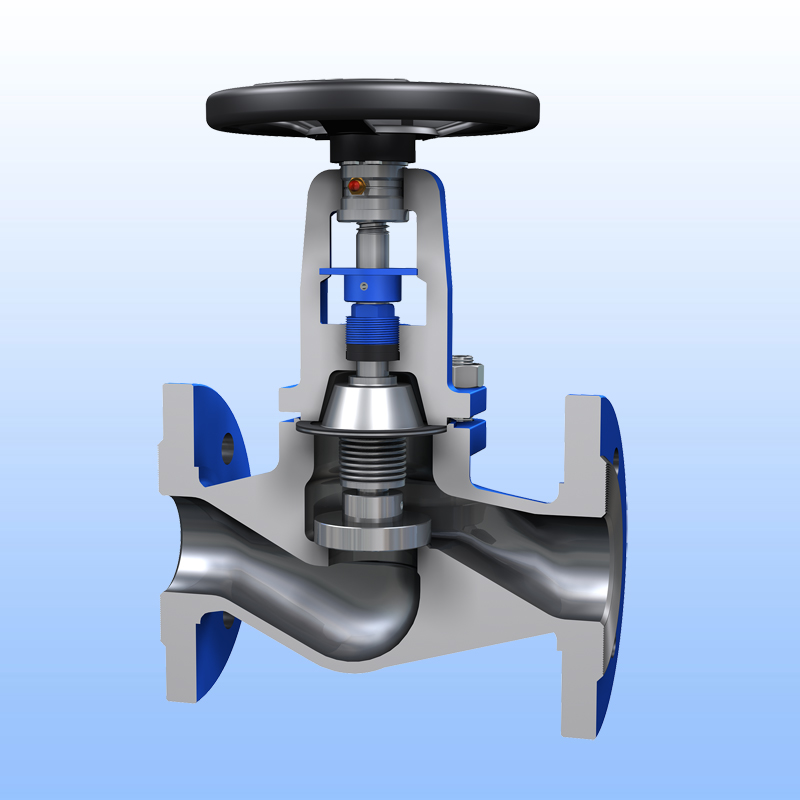

Bellows Seal Globe Valve,is normally designed and manufactured according to Germany standard and European standard EN13709.as normal,it's linear motion closing-down valve used to start, stop or regulate the flow using a closure member referred as a disc. the Bellows Seal Globe valves are most suitable and widely used to control or stop the flow of liquid or gas through a pipe for throttling and controlling fluid flow and are generally employed in small size piping.

it was invented to meet strict requirements of tightness and severe working conditions.except for the conventional packing assembly as all the gate valve,the bellows seal globe valve also has a bellow packing device.The accordion-shaped bellows is contained and protected inside the thick metal tube.One end of the bellows is welded to the valve stem, and the other end is welded to the protective tube. With the wide flange of the tube firmly clamped in the bonnet of the valve, a leak-free seal exists.

Bellows have a limited service life, which means the possibility of a rupture is likely. This is why a conventional packing assembly is always included in a bellows-equipped bonnet.So the bellows seal is an extra packing sealing for the gate valves,it's suitable for some severe working conditions.

normally there are three primary body patterns or designs for Bellows Seal Globe valves:

- 1).Standard Pattern (also as Tee Pattern or T – Pattern or Z – Pattern)

- 2).Angle Pattern

- 3).Oblique Pattern (also known as Wye Pattern or Y – Pattern)

Main features of Bellows Seal Globe Valve?

In particular chemical processes the fluids in the pipes are often toxic, radioactive and hazardous. Bellows seal globe valves are used to prevent leakage of any toxic chemical to the atmosphere. Body material can be selected from all available materials,The bellow can be supplied in different materials like 316Ti, 321, C276 or Alloy 625.

- 1).There is wide range of capabilities as available in standard pattern(streght pattern),Angle pattern,and Wye pattern(Y pattern).

- 2).Metal bellows seals the moving stem and increases durability of packed stem seal valves.

- 3).Two secondary stem seals: a) Backseat in open position; b) Graphite packing.

- 4).Bellow-sealed valves are usually leak tested using a mass spectrometer to detect leakage rates below 1x10E-06 std.cc/sec.Double sealing design (bellows seal and stem packing) if the bellows fail, valve stem packing will also avoid leakage,and in conformity with international tightness standards;

- 5).Easy Machining and resurfacing of the seats,for various purposes.

- 6)..Short travel distance of the disc(stroke) between the open and closed positions,Bellows seal globe valves are ideal if the valve has to be opened and closed frequently;

- 7).Widely used in all the countries in European union,and some other countries as well.

Technical Specifications of Bellows Seal Globe Valve?

Specifications of DIN-EN Bellows Seal Globe valve

| Design and Manufacture | BS1873,DIN3356,EN13709 |

| Nominal diameter(DN) | DN15-DN500 |

| Pressure rating(PN) | PN16-PN40 |

| Face to face | DIN3202,BS EN558-1 |

| Flange dimension | BS EN1092-1,GOST 12815 |

| Butt weld dimension | DIN3239,EN12627 |

| Test and inspection | DIN3230,BS EN12266 |

| Body | Carbon steel,Stainless steel,Alloy steel |

| Bellows | Stainless steel,Alloy steel |

| Seat | stainless steel,alloy steel,Stellite coating. |

| Operation | handwheel,manual gear,electric actuator,pneumatic actuator |

| Pattern of body | Standard pattern(T-pattern or Z-type),Angle pattern,Y pattern |

Product Show:

Applications of Bellows seal globe valves

Bellow Seal Globe Valve is widely used in pipeline with liquid & other fluids,especially for the fluids toxic,radioactive and hazardous

- Petrol/oil

- Chemical/Petrochemical

- The pharmaceutical industry

- Power and Utilities

- Fertiliser industry