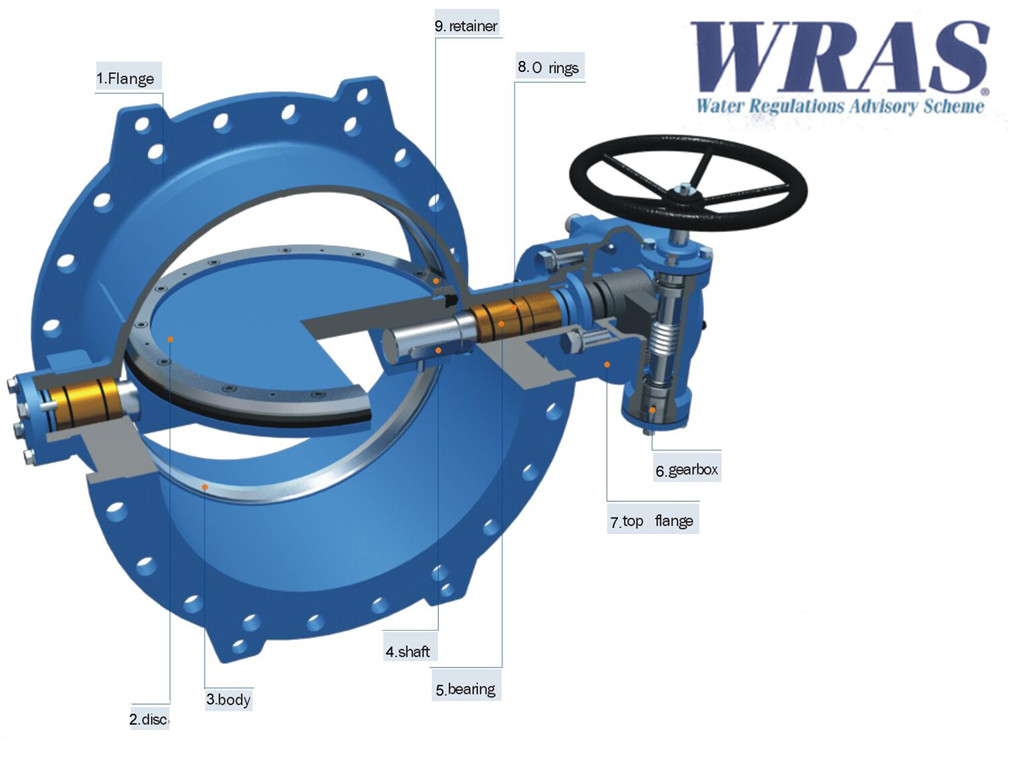

Double eccentric butterfly valve flange type Large Size with Gearbox China factory with high quality

What's Double eccentric butterfly valve flange type

Double eccentric butterfly valve flange type is an innovative double offset design product with advanced world leading technology. This butterfly valve has a unique structure with ultra reliable sealing performance, wide working conditions and low operation torque.

The double eccentric butterfly valve`s sealing ring is made of elastomer fit in disc, it availabe be used in unidirectional sealing application, Commonly used in the water or municipal water appliacation.

what makes it different from all the other butterfly valves,is the double eccentric or double offset disc design.

Double eccentric butterfly valve flange type ,with a seal ring fixed by cover plate,It will make the valve has a nonstop fixing surface on the circle and make the valve didn't touch the seat at all when it is completely opens. This design will make the seat encounter less friction and accordingly will extend its lifetime. In common application,this bi-directional balance butterfly valve is restricted to class 150.

it allows the disc to move off the seat reducing running torque and seat wear,it's a big advantage compared to the concentric butterfly valves.

Main features of NORTECHDouble eccentric butterfly valve flange type

Resilient seated

Double eccentric butterfly valve flange typeDesign standard: BS EN593

Face to face length : EN558-1/ISO5752 series 14& ISO5752 series 13

Flange dimension and drill : BS EN1092/BS4504 (DIN2501)

Size: DN350 – DN3000/ 14"-120"

Pressure rating:PN6- PN10-PN16-PN25-PN40

Application: water, drinking water, sewage, low-corrosive liquid etc.

WHY TO CHOOSE US?

Quick delivery,ready for shipment 1-4 weeks,with considerate stock of resilient seated butterfly valves and components

Quality guarantee 12- 24 months for resilient seated butterfly valves

Quality control for each piece of butterfly valve

Main feautres of Double eccentric butterfly valve flange type :

Longer service life due to tilted disc

The tension on the disc is released after a few degrees of opening which minimises wear of the disc seal. Furthermore, the design minimises the compression of the sealing which ensures low operating torques.

Twin seat designs

The integral seat design has a machined and epoxy coated ductile iron seat integrated in the body. The stainless steel seat design has a replaceable seat ring of stainless steel sealed with an O-ring to avoid leakages under the seat ring.

Shaft design features

The shaft sealing is replaceable under pressure to enable easy maintenance. Sealings of EPDM secure tightness from inside and out, and NBR sealings protect against impurities and fluids from outside.

Disc seal optimised for high performance

The disc seal is shaped to secure fixation in correct position providing a very reliable function. The excellent rubber quality makes it possible to reduce the amount of rubber which ensures low closing torques. The EPDM sealing is approved by ACS and WRAS.

Type of Operation for Double eccentric butterfly valve flange type

for Double eccentric butterfly valve flange type ,we provide

Manual gearbox operation,Pneumatic actuator,electric actuator,and hydraulic acatuators for your option.

Technical specifications of NORTECH double eccentric butterfly valves rubber seated?

| Design and Manufacture | EN 593/API609 |

| End Connection | Double flanged |

| Operation | Manual/Pneumatic/Electric |

| Size Range | NPS 14"-120"(DN350-DN3000) |

| Pressure Rating | 150 psi, 275 psi or 500 psi(PN10-16-25) |

| Face to face | EN558-1 series 13/series 14 |

| Flange | EN1092-2,ASME B16.5,AWWA C207,ASME B16.47 |

| Inspection | EN / AWWA C504/C519 / NSF 61/372 Certified |

Product Show:

Product Application:

What is the Double Eccentric Butterfly Valve rubber seated used for?

This kind of Double Eccentric Butterfly Valve rubber seated is widely utilized in

- Dams & hydropower

- Industrial,

- Irrigation,

- Power plants,

- Sewage & wastewater treatment,

- Water treatment