High Quality Wholesale Industrial full wafer butterfly valve China factory supplier Manufacturer

what's Full wafer butterfly valve ?

Full wafer butterfly valve Triple eccentric butterfly valve,also known as triple offset butterfly valve,is one kind of high performance butterfly valves,designed for working conditions of high pressure,high temperature,and high frequencies of open and close.

Concentric rubber lined butterfly valve,with mature design and manufacturing technology,are reliable in quality and friendly in cost.But for severe applications such as high temperatures or at high opening and closing frequencies,it’s not allowed to use the soft seat butterfly valves.So the hard seal butterfly valves,metal seat or ceramic seat,designed for high temperature,high pressure or high frequencies of open-shut,came into use,but the sealing performance of the traditional hard seal butterfly valve was always a big concern.

Full wafer butterfly valve Triple eccentric butterfly valve (also known as triple offset butterfly valve) has been invented in this case.

There are many characteristics for the triple eccentric butterfly valves.There is integral-to-body valve seat,with optimized seating angles,coated with anti-worn materials suitable for millions of opening and closing,stainless steel for corrosion resistance,and materials for high temperature.and the multi-layer soft sealing ring or hard sealing ring are fixed on the butterfly disc. This type of design allows makes the triple eccentric butterfly valve more resistant to thermal shocks or pressure peaks and corrosions,compared with traditional butterfly valves.

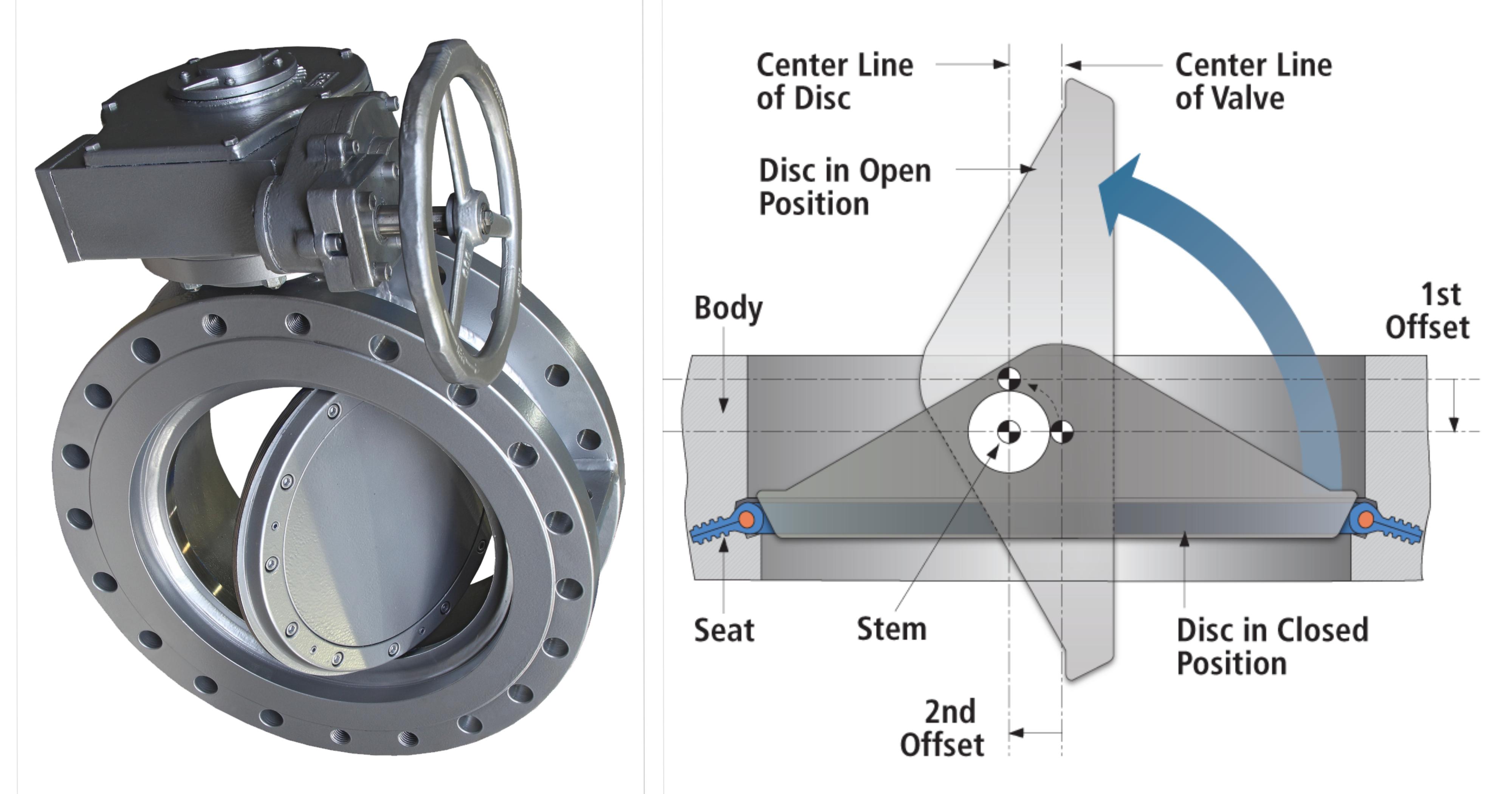

The Triple offsets design

- The first offset is that the valve shaft is behind the disc shaft so that the seal can completely close the entire valve seat.

- The second offset is that the centerline of the valve shaft is offset from the pipe and valve centerline to avoid interference from valve opening and closing.

- The third offset is that the seat cone axis deviates from the centerline of the valve shaft, which eliminates friction during closing and opening and achieves a uniform compression seal around the entire seat.

The above is the introduction of the Full wafer butterfly valve . It is a kind of high-performance butterfly valve currently used in many fields.

Main features of Full wafer butterfly valve

- Fire-resistant all-metal construction.

- Stellite® grade 6 seat overlays provide excellent durability.

- Open/closed disc references and external disc position indicator simplify installation/removal procedures to API 609.

- Two-piece packing gland and graphite packing minimize external emission risk.

- Key secured shaft-to-disc connection for maximum shaft integrity.

- Spiral wound gaskets, seal and packing rings replaceable with no special tools.

- Heavy duty bearings withstand high pressure loads and wear.

- Internal and external shaft extrusion risk handling complies with international standards.

Technical specifications of Full wafer butterfly valve

| Design | API 609/ASME B16.34 |

| End Connection | Wafer type,Lug type,Flanged type,Buttweld type |

| Operation | Manual/Pneumatic/Electric |

| Size Range | NPS 2"-60"(DN50-DN1500) |

| Pressure Rating | ASME Class150-300-600-900(PN16-PN25-PN40-63-100) |

| Flange standard |

DIN PN10/16/25, ANSI B16.1, BS4504, ISO PN10/16,BS 10 Table D, BS 10 Table E |

| Face to face |

ANSI B16.10,EN558-1 Series 13 &14 |

| Temperature | -29℃ to 450℃(depending the materials chosen) |

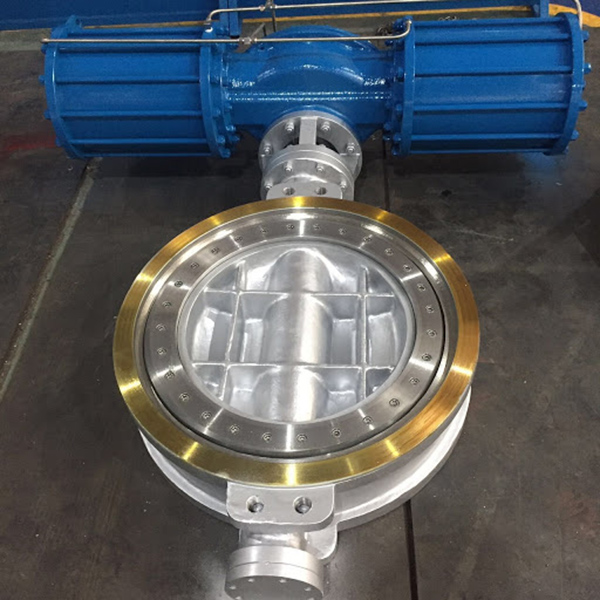

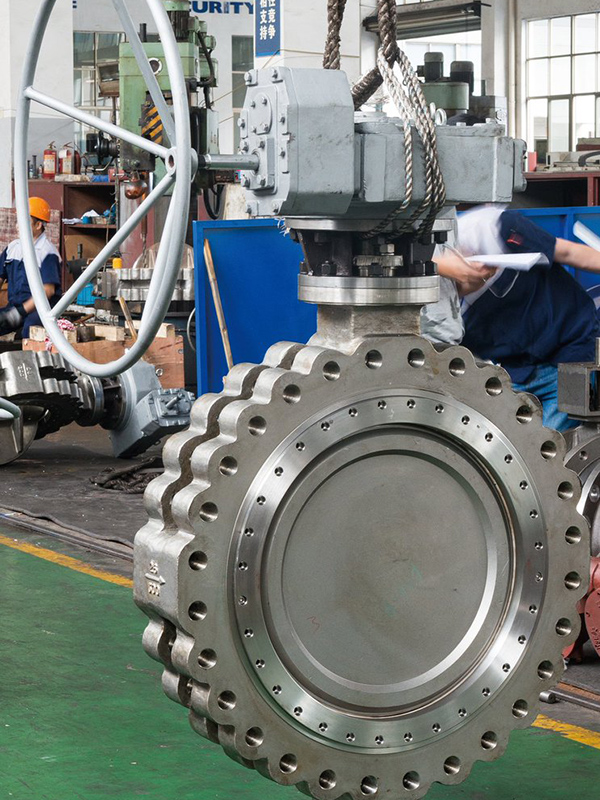

Product Show: Full wafer butterfly valve

Appilcation: Full wafer butterfly valve

This kind of Full wafer butterfly valve is suitable for handling the wide range of fluids in oil & gas, petrochemical, chemical, coal, desalination, waterworks, food & beverage industries. Also for solar, geothermal and hydro power, fossil fuels, district heating, mining, shipyards and the aerospace sectors.