Motorized China Whole Sale Ball Valve China factory

What's the Motorized ball valve ?

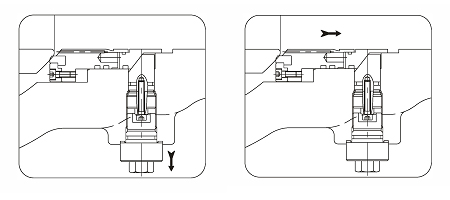

Motorized ball valve are valves that assembled its ball from top side part. It just like a globe valve that has body and bonnet except the trim part utilize a ball type. It comprises one single body. Top entry ball valves are used in piping systems where the top of the valve can be removed to gain access to the ball and seats without removing the entire valve from the piping system. Top entry ball valves are typically used in process systems where in-line maintenance is preferred over full valve removal. Therefore it’s very common to use top entry ball valves at high pressure application that require in-frequent maintenances such as HIPPS (High Integrity Pressure Protection System) valves etc. The advantages of the top entry ball valves is its construction that allow minimal thread connection so that it will also minimize possible leak path.

It is possible to remove the bonnet of the Motorized ball valve allowing free access to the body cavity without dismantling the valve from the line. A set of special maintenance tools permits to take out both ball and seat-rings; this maintenance operation requires very little space around the valve, thus allowing it in areas where space is a limiting factor.

Motorized ball valve is available in forged or cast execution, one-piece symmetric body closed by a bolted bonnet. It ensures that it has enough strength and rigidity under the maximum rated working pressure.The range includes both Full and Reduced bore, pressure ANSI class from 150 to 1500 , with all possible combination of ENDS connections: flanged (RF-RTJ), butt welding and HUB ends.

Main features of Motorized ball valve

- Meets ASME B16.5, B16.10 and B16.34, API 608, API 598, API 607 Rev. 5/ISO 10497.

- Wall thickness complies with ASME B16.34.

- Longer cycle life.

- Lower, uniform torque.

- Blowout-proof stem.

- Multiple solid cup and cone type PTFE stem seal or graphite packing.

- Valves can meet NACE specifications for sour gas service when required.

- Fire tested in accordance with API 607 Rev. 5/ISO 10497.

Technical specification of Motorized ball valve

NORTECH developed an advanced design of the Motorized ball valve in a complete wide range of diameters and pressure classes. Top-entry valves are the perfect choice when on-line maintenance is required.

- Double Block and Bleed

- Fire Safe Design Antistatic Device

- Sealant Injection Fitting

- Locking Device

- NACE

|

Design & Manufacture standards |

API 608,API6D |

|

Face to Face Dimension |

ASME B16.10,API6D |

|

Thread Connection Dimension |

RF/BW/RTJ |

|

Pressure-Temperature Rating |

ASME B16.34 |

|

Test And Inspection |

API598,API6D |

|

Type Of Operation |

Manual gear,Pneumatic actuator,Electric actuator |

|

DN(NPS) |

2"~36" |

|

PN(LB) |

150-1500lbs |

|

Material |

WCB,CF3,CF3M,CF8,CF8M |

|

Fire Safe Design |

API 607 or API 6FA |

The driving modes include

- handle lever operation,

- worm gear operation,

- pneumatic operation

- electric operation.

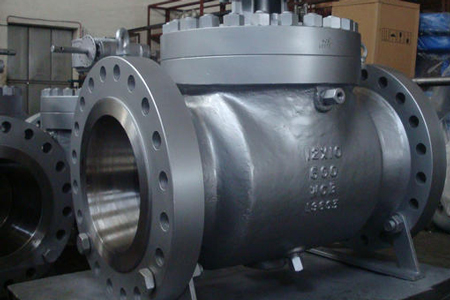

Products show:Motorized ball valve

Application of Motorized ball valve

It has such advantages as top online maintenance function, small fluid resistance, simple structure, reliable sealing, convenient operation and maintenance, rapid on-off operation, flexible opening and closing, etc.

This kind of Motorized ball valve is widely used in the exploiting,refining and transporting system of oil, gas and mineral. It can be also utilized to produce chemical products, medicine; production system of hydroelectricity, thermal power and nuclear power; draining system,widely utilized in pipelines and industrial systems.especially for the application when the on-line maintenance is required