Working principle and classification of check valve

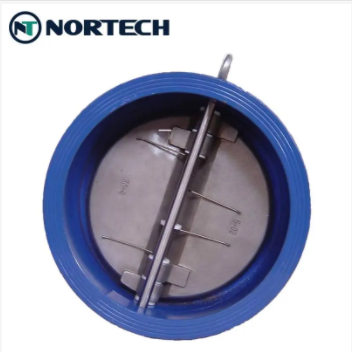

Check valve: check valve is also known as check valve or check valve, its role is to prevent the pipeline medium flow back. Water pump suction off the bottom valve also belongs to the check valve. The opening and closing parts are opened or closed by the flow and force of the medium to prevent the backflow of the medium valve called check valve. Check valve belongs to automatic valve class, check valve is mainly used for one-way flow of media on the pipeline, only allow media to flow in one direction, to prevent accidents. Check valve according to the structure, can be divided into lifting check valve, swing check valve and butterfly check valve three. Lift check valve can be divided into vertical check valve and horizontal check valve two. Swing check valve is divided into single disc check valve, double disc check valve and multi-disc check valve three. Butterfly check valve for straight-through check valve, the above several check valves in the form of connection can be divided into thread connection check valve, flange connection check valve and welding check valve three.

Check valve: check valve is also known as check valve or check valve, its role is to prevent the pipeline medium flow back. Water pump suction off the bottom valve also belongs to the check valve. The opening and closing parts are opened or closed by the flow and force of the medium to prevent the backflow of the medium valve called check valve. Check valve belongs to automatic valve class, check valve is mainly used for one-way flow of media on the pipeline, only allow media to flow in one direction, to prevent accidents. Check valve according to the structure, can be divided into lifting check valve, swing check valve and butterfly check valve three. Lift check valve can be divided into vertical check valve and horizontal check valve two. Swing check valve is divided into single disc check valve, double disc check valve and multi-disc check valve three. Butterfly check valve for straight-through check valve, the above several check valves in the form of connection can be divided into thread connection check valve, flange connection check valve and welding check valve three.

Check valve installation should pay attention to the following:

Do not load check valves in the line. Large check valves should be supported independently to protect them from pressure generated by the line.

When installing, pay attention to the direction of the flow of media should be consistent with the direction of the arrow of the valve body.

Lift vertical flap check valves should be installed in vertical piping.

Elevating horizontal disc check valves should be installed in horizontal pipelines.

Main performance parameters of check valve:

When installing, pay attention to the direction of the flow of media should be consistent with the direction of the arrow of the valve body.

Lift vertical flap check valves should be installed in vertical piping.

Elevating horizontal disc check valves should be installed in horizontal pipelines.

Main performance parameters of check valve:

Nominal pressure or pressure level: PN1.0-16.0mpa, ANSI Class150-900, JIS 10-20K, nominal diameter or diameter: DN15~900, NPS 1/4~36, connection mode: flange, butt welding, thread, socket welding, etc., applicable temperature: -196℃~540℃, body material: WCB, ZG1Cr18Ni9Ti, ZG1Cr18Ni12Mo2Ti, CF8(304), CF3(304L), CF8M(316), CF3M(316L), Ti. Choose different materials, check valve can be respectively suitable for water, steam, oil, nitric acid, acetic acid, oxidizing medium, urea and other media.

Nortech is one of the leading industrial valve manufacturers in China with quality certification ISO9001.

Major products: Butterfly Valve, Ball Valve,Gate Valve, Check Valve, Globe Vavlve,Y-Strainers, Electric Acurator , Pneumatic Acurators .

Post time: Oct-12-2021