Parallel Slide Gate Valve 2

What is the parallel slide gate valve?

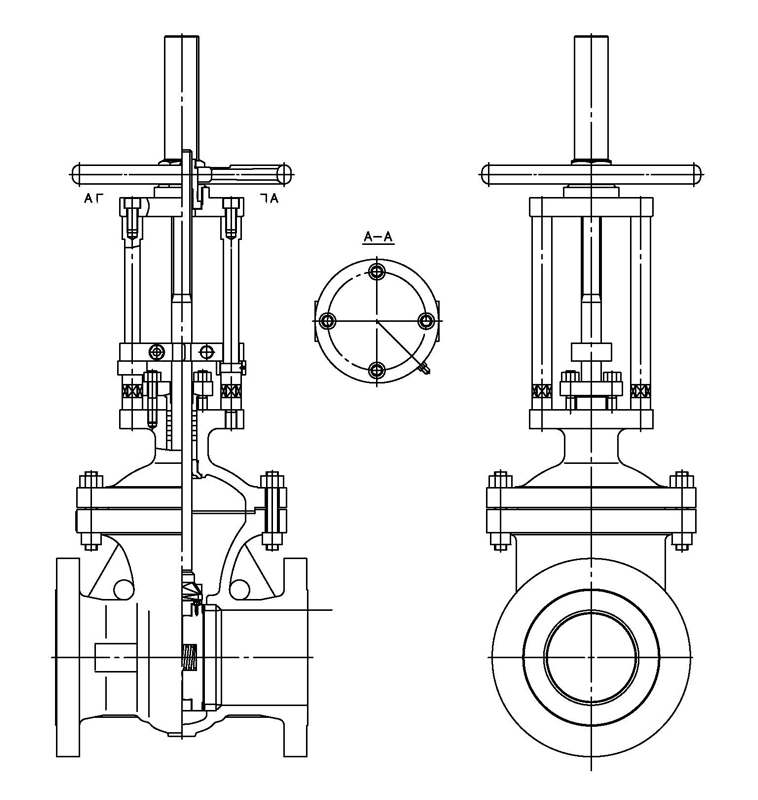

Parallel Slide Gate Valve is a special design of gate valve.

It’s an alternative to the traditional flexible wedge type gate valves. The disc is in two halves, compressed spring Inconel X750 loaded, that seat on parallel seat rings. The disc “slides” in contact with the seats, hence the name.

The discs are in permanent contact with the seat rings, getting a tight seal due to the horizontal inconel spring located in between and without the wedging system help.

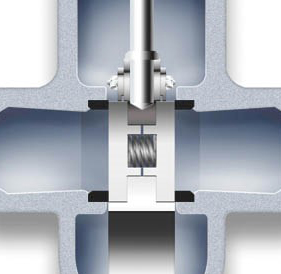

Sealing mechanism of the parallel slide gate valves.

- When the pipe pressure or pressure difference of two sides is small,the compressed spring will push the discs to the sealing rings,it’s the initial sealing of the parallel slide gate valves under low pressure conditions.

- When the pipeline pressure increase,the increasing line pressure will push the disc against the seat ring with force in the low pressure side,which creates the secondary seal. The higher the medium pressure,the better the sealing performance

Therefore this valve type is widely used in high pressure and high temperature services such as steam and feedwater.

The advantages of the parallel slide gate valve versus the traditional wedge type product are:

- The discs of parallel slide gate valve will never block in closed position,while it may occur with a wedge type that has been closed with the line in temperature and opened when the line is cold.

- The opening/closing torque of parallel slide gate valve is much lower than a corresponding gate valve wedge type valve,resulting in smaller actuator and less expensive actuation systems.

- The “sliding” feature keeps dirt away from the sealing surfaces.

Main features of NORTECH Parallel slide gate valves

Design Features

- Tight shut off achieved by line pressure— not from mechanical wedging action therefore eliminating thermal binding

- Minimum pressure drop

- Discs are self-aligning.

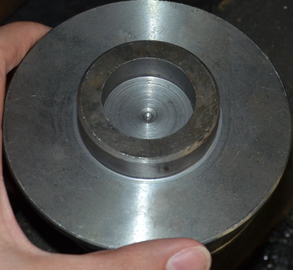

- Disc are coated with hard faced alloy Stellite Gr6.

- Bi-directional shut off to API 598

- Self cleaning action between disc and seat

- Bypass arrangement available

- Available in high temperature carbon steel, chrome-moly steel, and stainless steel materials of contruction: ASTM A216 GR WCB, ASTM A217 GR WC6, ASTM A217 GR, WC9, and ASTM A351 GR CF8M.

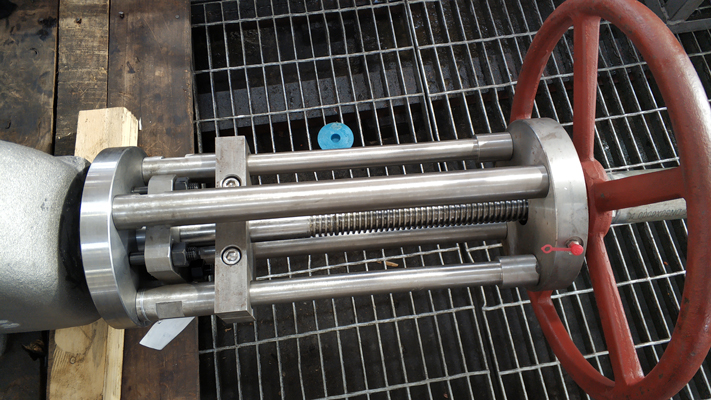

- Available with manual operator, or fitted with suitable actuator of choice

| Product name | Parallel slide gate valve |

| Nominal diameter | 2”-24”(DN50-DN600) |

| End connection | RF,BW,RTJ |

| Pressure rating | PN16/25/40/63/100/250/320,Class 150/300/600/900/1500/2500 |

| Design standard | ASMEB16.34,API 6D |

| Working temperature | -29~425°C (depending on materials chosed) |

| Inspection standard | API598/EN12266/ISO5208 |

| Main application | Steam/Oil/Gas |

| Type of operation | Handwheel/Manual gearbox/Electric actuator |

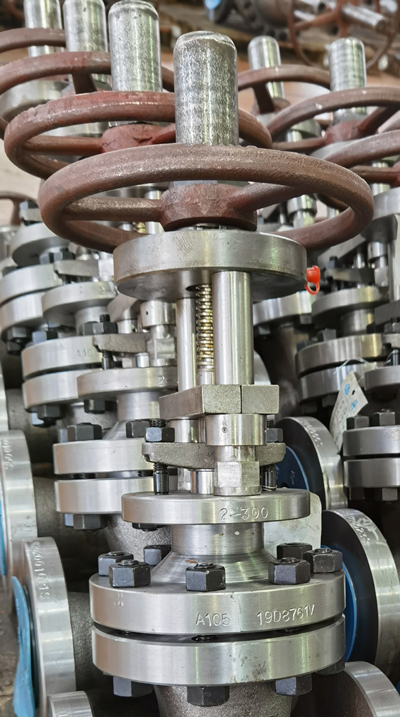

Disc and Spring of the parallel slide gate valve:compressed spring in inconel X750 is placed between two discs in parallel position.

Pillar and Bridge BBOSY of the parallel slide gate valve:Pillar & bride BBOSY design,the York is designed with 2 or 4 forged steel pillars,depending on the valve diameter.

Hydraulic test of NORTECH Parallel Slide Gate Valve

Inspection of parallel slide gate valves.

- shell test 1.5 times of rated pressure

- low pressure seal test with air 0.6 Mpa

- low pressure seal test with water 0.4 Mpa

- middle pressure seal test from 0.4 Mpa to 1.0Mpa

- high pressure seal test 1.1 times of rated pressure

Product Show:

Where is the Parallel Slide Gate Valve used?

Parallel Slide Gate Valve is widely used in the field chemical,petroleum, natural gas,oil and natural gas production wellhead device, conveying and storage pipelines (Class150~2500/PN1.0~42.0MPa, operating temperature -29~450℃),pipes with suspended particle media,urban gas pipeline,water engineering.it's designed to provide isolation and transmission of flow in a piping system or a component when closed, sometimes can be installed in the pump outlet for regulating or control of flow.