Pneumatic Ball Valve Stainless Steel Floating Ball Valve China factory

What's Pneumatic ball valve ?

A Pneumatic ball valve uses a rotating ball and a stem that provide on/off flow control.

The Pneumatic ball valve utilize natural line pressure to press and seal the ball against the downstream seat. The line pressure is exposed to a greater surface area - the entire upstream face of the ball, which is an area equal to the actual pipe size.

A Pneumatic ball valve is a valve with its ball floating (not fixed by a trunnion) inside the valve body, it drifts toward to the downstream side and tightly pushes against the seat under the medium pressure to ensure sealing reliability. The floating ball valve has simple structure, good sealing performance but the seat material is required to withstand the workload since the sealing pressure is bared by the seat ring. Due to unavailability of high performance seat material, floating ball valve is mainly used in middle or low pressure application.

Main features of NORTECH Pneumatic ball valve ?

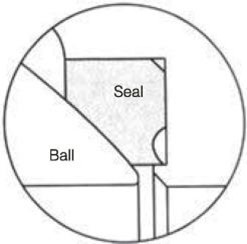

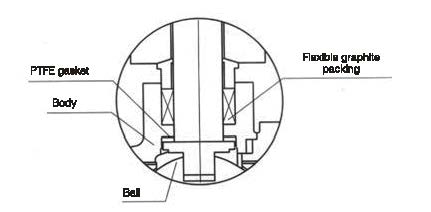

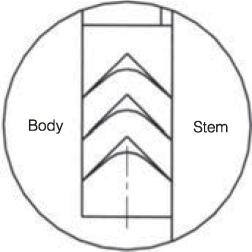

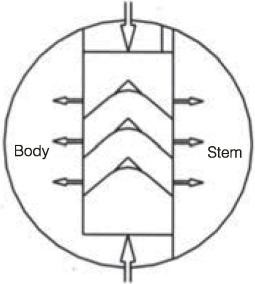

1. Special Seat Design

we adopts the design of flexible seal ring structure for the floating ball valve. When the medium pressure is low,the contact area of seal ring and ball is small. It will reduce friction and operating torque and ensure the tightness in the same time.When the medium pressure is increased,the contact area of seal ring and ball becomes bigger along with the elastic deformation of seal ring, so the seal ring can endure higher medium impact without being damaged.

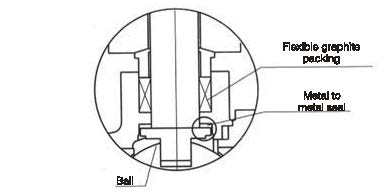

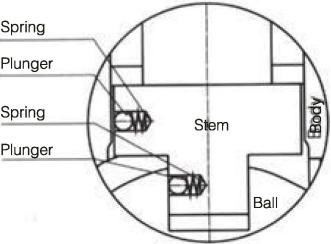

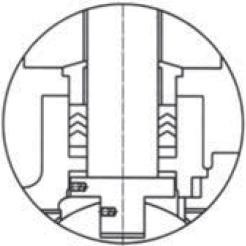

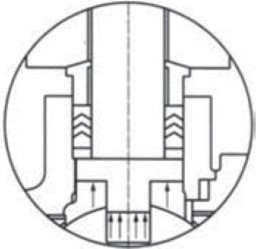

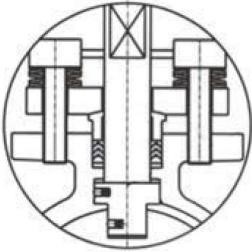

3. Anti-static Structure

The ball valve is designed with the anti- static structure and the static electricity discharge device to directly form a static channel between the ball and body through the stem so as to discharge the static electricity produced of friction of ball and seat,avoiding fire or explosion that may be caused by static sparkle and ensuring system safety.

floating seat under low pressure

floating seat under high pressure

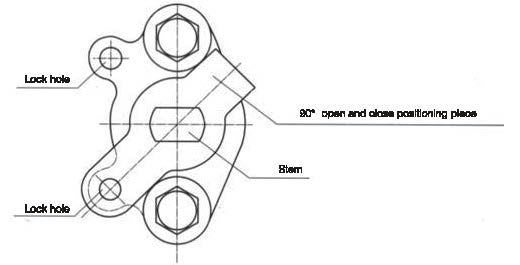

5. Lock and Misoperation Prevention

The manual ball valve can be locked by a lock at the full Open or full close position. The 90° open and close positioning piece with lock hole is designed to avoid valve misoperation caused by non-authorised opreators, and it can also prevent valve opening or closing, or other accidents caused by pipeline vibration or unpredictable factors. It is very effective especially for inflammable and explosive oil,chemical and medical working pipelines or field tubing. The part on the head of the stem that is installed with the handle adopts flat design. Where the valve is opened, the handle is parallel to the pipeline, and closing indications of the valve are guaranteed to be correct.

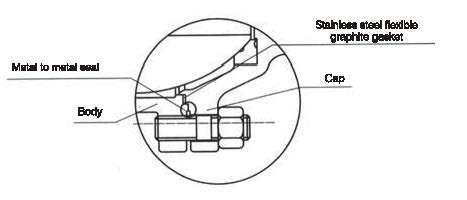

Fireproof Structure Design of middle flange

Fireproof Structure Design of Stem(after burning)

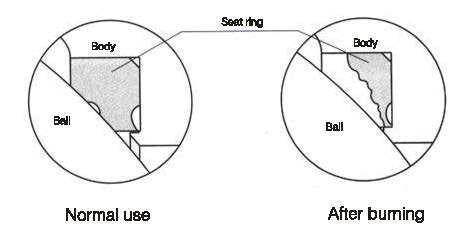

Fireproof Structure Design of Seat

Fireproof Structure Design of Stem(normal use)

Anti-Static structure design of ball valve with DN32 and above

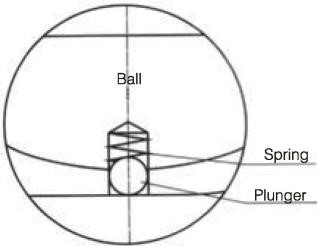

Anti-Static structure design of ball valve smaller than DN32

bottom mounted stem will not blown out under medium pressure

top mounted stem may blow out under medium pressure

Before the packing is pressed

After the packing is pressed

the Spring loaded packing mechanism

Technical Specifications of floating ball valve?

| Nominal diameter |

1/2”-8”(DN15-DN200) |

| Connection Type |

Raised face flange |

| Design standard |

API 608 |

| Body material |

Stainless steel CF8/CF8M/CF3/CF3M |

| Ball material |

Stainless steel 304/316/304L/316L |

| Seat material |

PTFE/PPL/NYLON/PEEK |

| Working temperature |

Up to 120°C for PTFE |

|

|

Up to 250°C for PPL/PEEK |

|

|

Up to 80°C for NYLON |

| Flange end |

EN1092-1 PN10/16,ASME B16.5 Cl150 |

| Face to face |

ASME B 16.10 |

| ISO mounting pad |

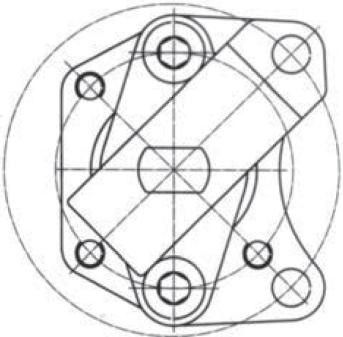

ISO5211 |

| Inspection standard |

API598/EN12266/ISO5208 |

| Type of operation |

Handle lever/Manual gearbox/Pneumatic actuator/Electric actuator |

Product Show:Pneumatic ball valve

Application of Pneumatic ball valve

Our Pneumatic ball valve can be widely utilized in petrochemical, chemical,steel,paper making, pharmaceutical and long-distance transport pipes.etc,nearly all the field.