China Rubber seat gate valve Whole Sale China factory Supplier

What's Rubber seat gate valve ?

Rubber seat gate valve, a design principle that is dominant in preference for use in distribution systems.

The Rubber seat gate valve contains a wedge fully encapsulated with EPDM rubber that is permanently bonded to the wedge and meets ASTM D249. The valve body, bonnet, and stuffing plate are coated with fusion bonded epoxy (FBE) ,beautiful looking and excellent protection. Optional configurations also include a Non-Rising Stem (NRS) or Outside Screw & Yoke (OS&Y).

Rubber seat gate valve also can be operated with a Spur or Bevel Gear,and electric actuator.

Main features of NORTECHRubber seat gate valve

The body is made of ductile iron by precision casting moulding,It was designed by 3D software,with finite element analysis for the structure.The safety coefficient is over 2.5.Smooth bottom channel is designed,to avoid accumulation of impurities and to ensure small flow resistance.

The stem is made of stainless steel by rolling. Integral type,avoiding the use of the brass half rings to reduce stem diameter. the smooth modified ladder type screw is extruded. Global mirror polish,it fits the O rings well, to ensure that the smooth rotation and small torque.

The frame of the wedge is made of ductile iron by the precoated sand moulding,the wedge is covered by EPDM totally.Double seal design,each seal line can work independently

The grade 8.8 bolts connect the bonnet and the body, the bolts were covered by hot-melt wax which protects the bolts for corrosion. The gasket between the bonnet and body is made of EPDM. The valve cover is machined with a retaining groove,make sure that the rubber gasket won't be extruded out under high water pressure.

Environmental friendly manufacturing

The inside and outside surface of the valve is coated with sanitary epoxy powder by fusion bonded epoxy(FBE), the average thickness is above 250um. The adhesion of the coating is strong,it won't be destroyed under the impact force test of 3J. Internal parts can meet with the environmental protection requirements,and can be used for the potable water,food and pharmaceutical area directly.The electrostatic powder coating process can promise high adhesion force and strong corrosion resistance

Easy installation and operation

We offer various kinds of interface such as flange connection,PVC pipe socket, uctile iron pipe socket,reducing etc.The special connection design can be customised as per the requests

of users.

The valve can be completely closed and reach at o leakage with small torque. The actual operating torque is only 80% of diameter, and the gate valves can bear the MST of 3*DN N.M. The products passed the life test of 5000 times. For the valves of large diameter, we can offer the labour saving devices, to ensure that all the valves can be opened and closed by one person. The handwheel is strong, with accurate dimensions, it fits well with the valve stem, the shape is in accordance with human mechanics, to ensure easy operation

Easy maintenance

The seal ring can be replaced without cutting off the water,it's easier for the maintenance and reduce the maintenance time as much as possible.Very small friction between the brass bushing and the "O" type seal,it will ensure long life of the seal ring.The max. operating torque is under the control.

Specifications of NORTECH Rubber seat gate valve

DIN3352 F4/F5,EN1074-2,BS5163 Type A,AWWA C509

| Design and Manufacture | DIN3352 F4/F5,EN1074-2/BS5163/AWWA C509 |

| Face to face | DIN3202/EN558-1/BS5163/ANSI B16.10 |

| Pressure rating | PN6-10-16,Class125-150 |

| Size | DN50-600 OS&Y Rising stem |

| DN50-DN1200 Non-rising stem | |

| Rubber wedge | EPDM/NBR |

| Appilcation | Water works/Drinking water/sewage etc |

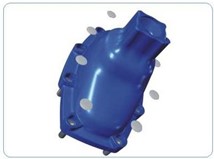

Product Show: Rubber seat gate valve

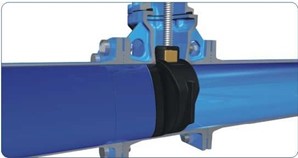

Application of NORTECH Rubber seat gate valve